5 Places to Love Corrugated Metal in Your House

Corrugated metal’s flexibility, both physical and aesthetic, means lots of options for inside use: ceilings, walls, staircases and furniture, for starters. The material is also available in an array of finishes and sizes to harmonize with a gamut of styles — from rustic to industrial.

Corrugated metal is made in panels typically between 24 and 40 inches wide and 8 feet long or longer, making it a great solution for cladding walls.

The corrugations, or waves, come in various profiles. A slim profile, meaning the waves are smaller and closer together, would be around 1¼ inches by ¼ inch. A large profile would be in the neighborhood of 2¾ inches by ⅞ inch. The first number indicates the on-center dimension between the waves, while the second is the overall panel height.

Steel is the most popular material for new corrugated metal panels. However, some manufacturers, such as Steelogic Metal Systems, offer them in aluminum, copper and Galvalume, a zinc-aluminum alloy with an anticorrosive matte finish.

The material cost for corrugated metal panels is less than or comparable to that for drywall, but corrugated metal doesn’t require the finishing and painting that drywall does. In most cases corrugated metal panels save time and money. Expect to pay $1.25 per square foot for basic new panels, and around $2 for higher-end finishes and prints.

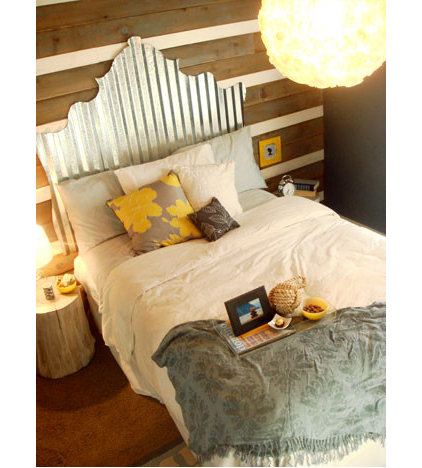

Panels installed horizontally have a more contemporary or edgier look. A vertical orientation is more conventional. Here vertical panels with cool industrial stamping give a bedroom the right amount of rustic vibe without being campy.

Reclaimed panels usually have some rust and a pleasant patina and are specifically sought out for these characteristics. The advantage of buying new is that the panels can be ordered in a gauge and profile suitable for the project’s application and support requirements. Panels are typically fastened to wood or metal stud framing or oriented strand board. If they’re being installed over existing drywall, they need to be fastened to the wall at stud locations.

Light from this kitchen skylight plays on the gleaming, undulating surface, making the ceiling the visual focus of the room.

Corrugated metal panels are flexible enough to navigate the tight twists of this spiral staircase. Laura Kirkland of Bridger Steel says one corrugated panel can be bent enough to create a full circle or just a gentle arc — it all depends on the gauge and profile of the metal. Show your plans to the manufacturer to get the right material for your curved project.

Corrugated metal paneling isn’t only for cladding wall and ceiling surfaces. With its durability and easy maintenance (you just need to wipe it with water), it makes a great kitchen cabinet facing.

With cabinet fronts, the tricky part is how to fasten and treat the edge of the material. On this kitchen island, trim seals the exposed edges. Kirkland notes that fasteners and trim are a “fun element, because you can match the metal or choose a contrasting color for a great accent.”

Set no limits with corrugated metal panels. It looks great on furniture too, as you can see with this whimsical headboard.

Corrugated metal panels are fairly easy to cut. A saw blade for cutting steel is the usual recommendation. Ryan McNary at Elmwood Reclaimed Timber notes that the company’s reclaimed corrugated tin is light enough to be cut, yet sturdy enough to hold its shape.

Don’t think that all new panels have to look new. Some manufacturers can treat the panels to look weathered. The bathroom wall shown here, by Bridger Steel, has new corrugated paneling with the company’s Truten finish for an aged look.